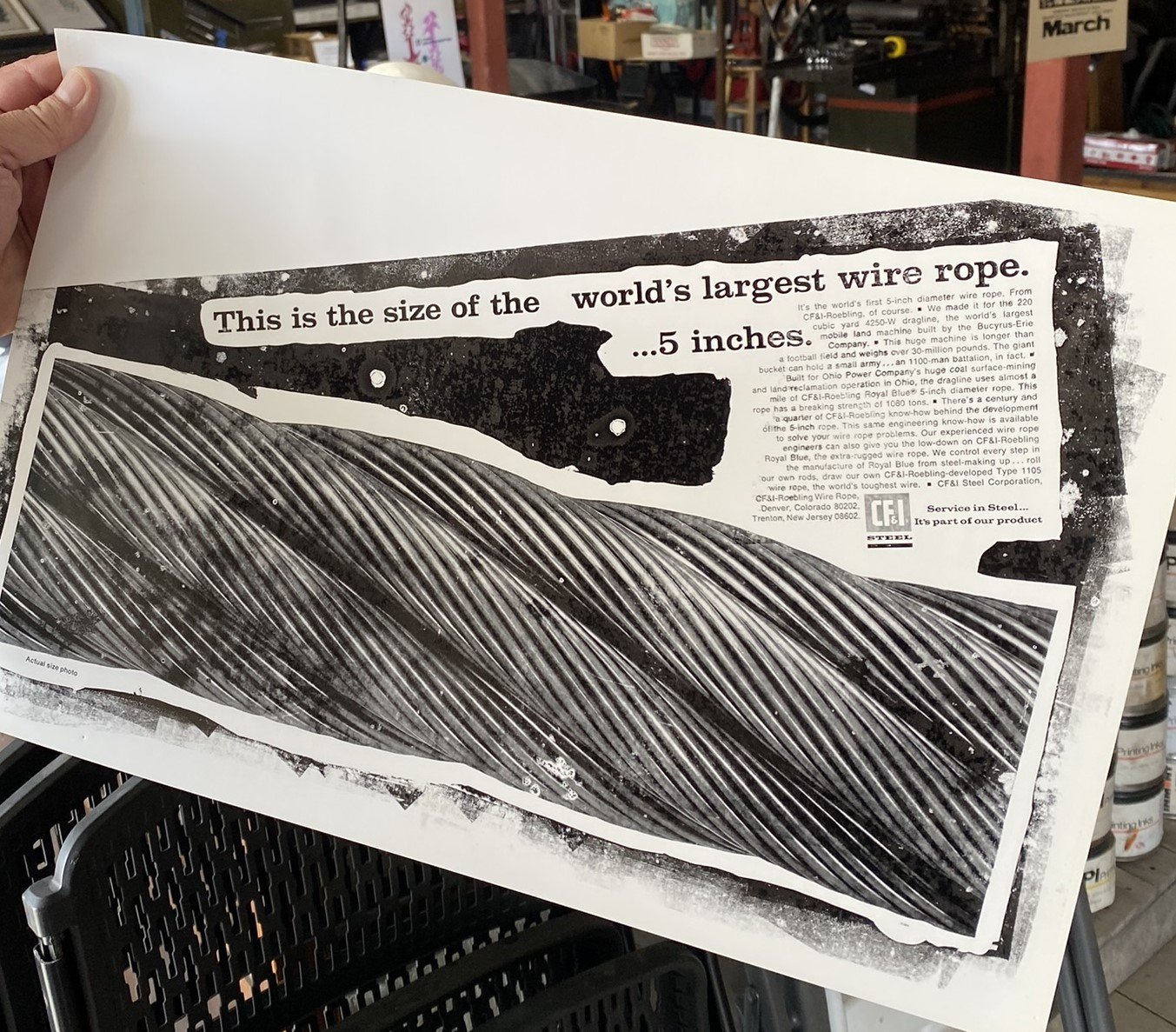

An etching press found at an estate sale saw its first action this past week when Albert Gallo brought over a large copper printing plate to proof. Albert describes himself as “husband, son, brother, hard worker, thinker of things, maker and avid bike rider. Collector of hobbies.” Fresh from printing at Ridgefest in Wheat Ridge, he wanted to see what this strange large printing plate he had acquired looked like.

Tom Parson thought of our new etching press. Normally used for intaglio printing, an etching press consists of metal rollers between which a flat press-bed slides under pressure. A design is acid-etched or engraved into a plate which then has ink rubbed into its grooves. After the surface of the plate is wiped clean, heavy pressure is applied and the design is transferred to paper. It’s the opposite of relief printing where the material (like type) is raised and the inked surface is printed.

But a press like this can also be used for relief printing if the rollers are adjusted, useful for situations where the item to be printed is not type high (all items in letterpress printing must be 0.9186 high). So in went Albert’s copper plate

And out came

This plate of the world’s largest wire rope is now in the Depot collection, donated by Albert.

Also this week, Alicia McKim’s class from the Rocky Mountain College of Art and Design came to visit and printed wood type and cuts from our collection on a Vandercook proof press.

All this in the shadow of work being done by Tom and visiting Seattle printer, writer and Depot supporter Paul Hunter on the challenging Challenge press, model 1528KA. This cylinder proof press had seen some hard times and needed a lot of TLC.

They hoped a broken cast iron part could be welded.

But sadly the weld did not hold. In fact, two replacement parts for the 1528KA will be needed to fix this beautiful press. Where in the world? Or it will have to be offered out as parts for someone else’s project. Heavy metal inky hope!